- (+86) 021-60870195

- No.2555,Xiupu Road, Pudong, Shanghai

- [email protected]

No.2555,Xiupu Road, Pudong, Shanghai

(+86) 021-60870195

We Sincerely Welcome You To Contact Us Through Hotlines and Other Instant Communication Ways.

Graphite, which is used as a commercial anode material, is increasingly unable to meet the increasing demand for high capacity of anode materials due to its limited theoretical capacity. If asphalt is used as carbon precursor in the anode of lithium ion battery, it can not only realize the high value-added utilization of asphalt, but also provide some new methods and exploration for the improvement of electrochemical performance of anode materials.

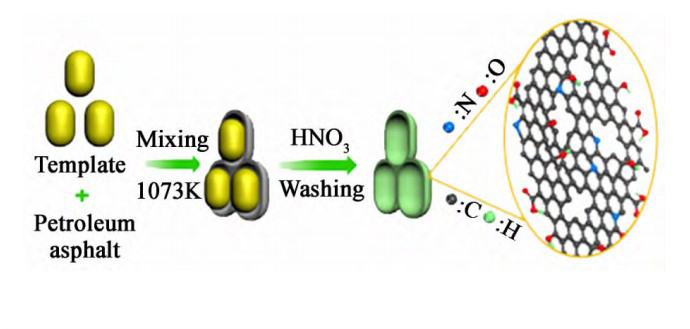

Li P et al. prepared ultra-thin porous carbon shells (PACS) with unique hollow structure by using nano-sized magnesium oxide particles as template and petroleum asphalt as carbon source, after ultrasonic dispersion in liquid phase and high-temperature treatment at 800 ℃ for 1 h under the protection of nitrogen. PACS has A reversible capacity of 334 mAh· g-1 and A capacity retention rate of 90% after 1 000 cycles at A current density of 1 A·g-1 due to its ultrathin lamellar structure and hierarchical porous structure.

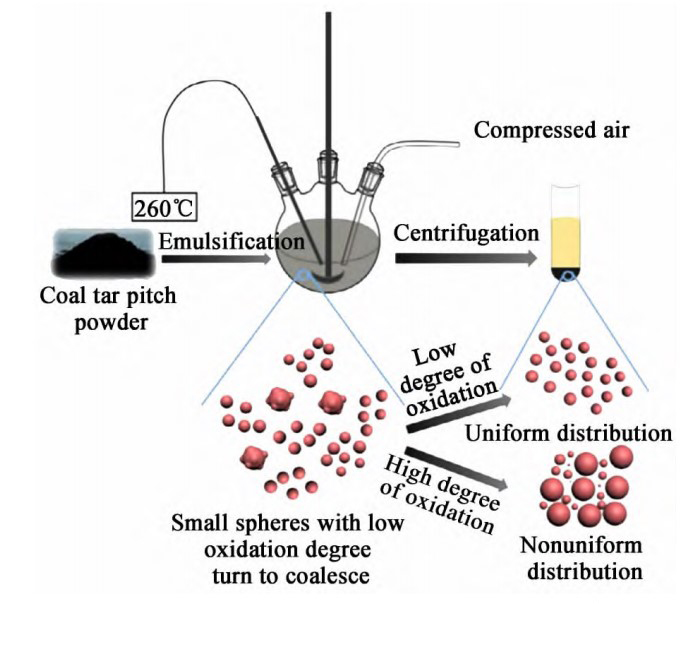

Yuan M et al. prepared bituminous carbon microspheres (PCBS) by spheroidization stabilization method using low-cost coal tar pitch as raw material. In the preparation process, oxygen in the air is introduced to promote cross-linking, thus avoiding the coalescence of asphalt with low softening point in the emulsion. There is no need for post-treatment to stabilize its spherical form. When used as anode material of lithium ion battery, the gram capacity of PCB is 373.6 mAh·g-1, 125.8 mAh·g-1, and the volume capacity is 316.1 mAh·cm-3 respectively at the current density of 0.05 A·g-1 and 5 A·g-1. 106.4 mAh · cm - 3.

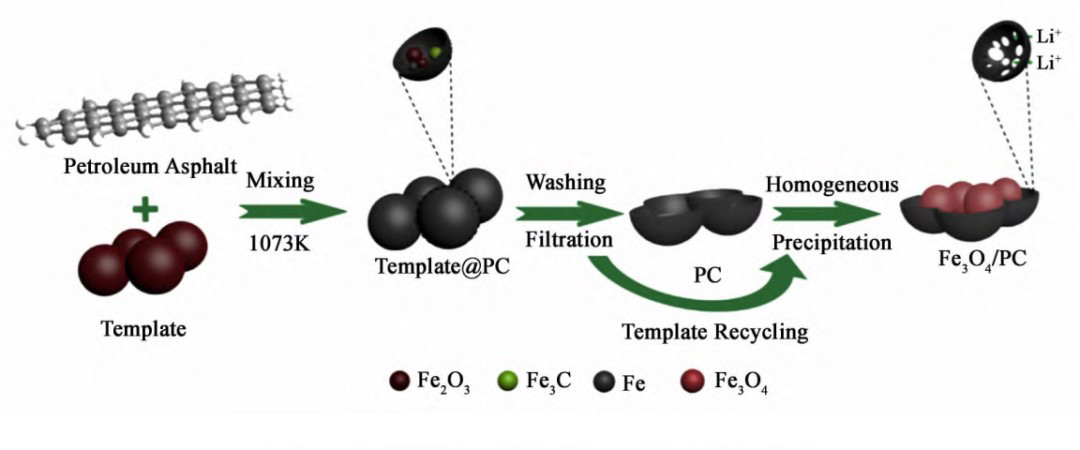

Liu Y et al. used petroleum asphalt as carbon source and Fe2O3 as template. In the process of pickling and removing the template, the filtrate was recovered and coprecipitated to prepare nano-Fe3O4 / petroleum asphalt based carbon (Fe3O4/PC) composites. Fe3O4/PC with 73% Fe3O4 can provide a reversible capacity of 785 mAh·g-1 at 200 mA ·g-1 when used as anode material for lithium-ion batteries.

Wang T et al. used asphalt as carbon precursor, KOH activated and composite with graphene nanoribbons, and coated lithium metal on the surface of carbon composite by electrochemical deposition process. When lithium metal was used as anode, coulomb efficiency reached above 96% after 500 cycles at 1.3C. When Li∶C was 1∶1, When the current density is 20 mA/cm2, the area capacity is 9.4 mAh/cm2.

Song X et al. used nanometer layered MgO as template, asphalt as carbon precursor, carbonized it, activated it, purified it, graphitized it at 1 400 ℃, and obtained activated carbon (HPC) with layered pore structure, which was used as the positive and negative poles of lithium ion capacitor. When the current density was 0.5 A·g-1, The specific capacitance is 340 F·g-1, and the capacitance retention reaches 91.3% after 1 000 cycles.

The carbon material based on asphalt can be used as the negative electrode to improve the value of asphalt, but because of the complex composition of asphalt, the capacity of asphalt material itself is not high, if it is directly used as the negative material, it needs to carry out the microstructure design, and it is difficult to mass production, and the cost is too high. Therefore, asphalt is usually used as a modified material in the production process to achieve high value-added utilization of asphalt.

2 Asphalt Modified Anode Material

Surface coating is one of the most commonly used methods to modify anode materials in industry at present. This method forms a layer of amorphous carbon on the surface of materials by solid phase, liquid phase or gas phase carbonization to build a "core-shell structure". The "shell structure" of the surface can effectively restrain and buffer the volume expansion or structural damage of the active center of the anode material, while increasing the compatibility with the electrolyte and maintaining the stability of the electrode material.

2.1 Asphalt-Coated Graphite

Graphite as anode material of lithium ion battery still has many problems, such as in the process of charging and discharging, lithium ion embedment and stripping lead to the lamellar peeling and structure destruction of graphite, graphite and electrolyte compatibility is poor, lithium ion in graphite chemical diffusion coefficient is small. In order to solve these problems, graphite needs to be modified. As a common carbon source of modified graphite, asphalt has been widely concerned by researchers.

Recently, Han Y J et al. [studied the influence of composition and softening point of coal tar pitch on the first Coulomb efficiency and rate performance of the graphite anode coated by coal tar pitch.The results show that the asphalt with higher softening point and less light component is more likely to form uniform amorphous carbon coating on graphite surface, which can effectively reduce the charge transfer resistance between graphite electrode and electrolyte interface, thus enhancing the electrochemical performance of graphite coated anode.

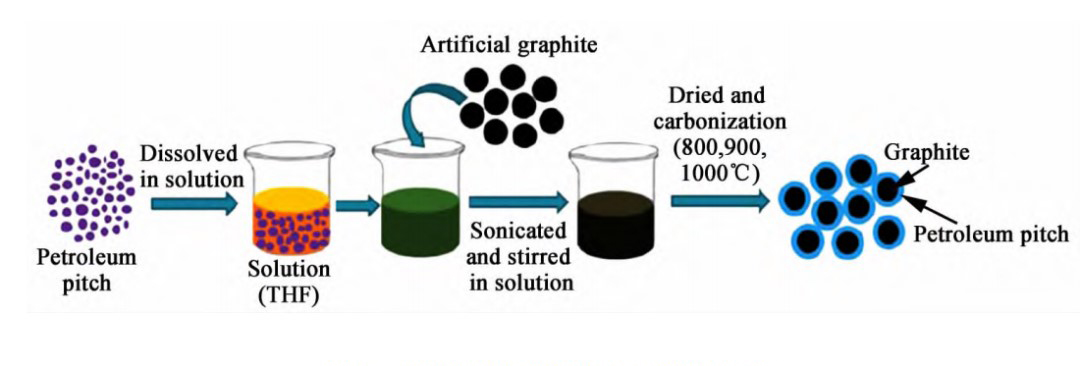

Yoon Ji Jo et al. coated the artificial graphite surface with petroleum asphalt with three different softening points (150, 200 and 250 ℃) to explore its influence on the electrochemical performance of graphite anode. When the carbonization temperature is 1 000 ℃ and the asphalt coating mass fraction is 10%, the asphalt coated graphite anode with softening point of 250 ℃ shows the best electrochemical performance: The first Coulomb efficiency is 92.9%, and the capacity is 343 mAh· g-1, and the capacity retention rate is 84.1% at 10C/ 0.1c.

Im U S et al. mixed asphalt and natural graphite in toluene solution and stirred them. After the solvent evaporated to form asphalt coated graphite, it was activated at low temperature for 1 h under air atmosphere. Finally, it was carbonized at 800 ℃ for 3 h under nitrogen atmosphere at a heating rate of 5 ℃·min-1. The effect of low temperature activation on graphite anode material coated with pitch for lithium ion battery was studied. The results show that low temperature activation can control the structure of bitumen coating and improve the rate performance (1C/ 0.1c, capacity retention rate is 91.0%) and cycle stability (capacity retention rate is 86.3% after 30 cycles at 0.5C).

Kim K J et al. mixed microcrystalline graphite powder (MG) in tetrahydrofuran solution containing dissolved asphalt as carbon precursor, then coated the precursor on the surface of hard carbon material, heated at 1 200 ℃ for 1 h in argon atmosphere, and obtained hard carbon/microcrystalline graphite/carbon composite with core-shell structure. Their electrochemical properties were characterized. The results show that when the mass ratio of hard carbon /MG/ pitch carbon is 30/50/20, the first Coulombic efficiency of the composite is 89.8%, and the capacitance retention of the composite can reach 97% of the initial value after 250 cycles.

2.2 Asphalt-Modified Silicon Anode

Compared with graphite anode, silicon has higher theoretical capacity, moderate lithium ion deinlay potential (0.4V) and better safety performance, etc., which is a promising anode material for the next generation of lithium ion batteries. However, silicon material has poor electrical conductivity, which leads to volume expansion in the charging and discharging process, resulting in its reversibility instability and serious capacity attenuation. Meanwhile, its high price limits its application development. By coating silicon with asphalt, carbon coating can be formed on its surface to stabilize SEI film and buffer volume expansion, so as to enhance the cycling performance, thus effectively improving the stability of electrode material.

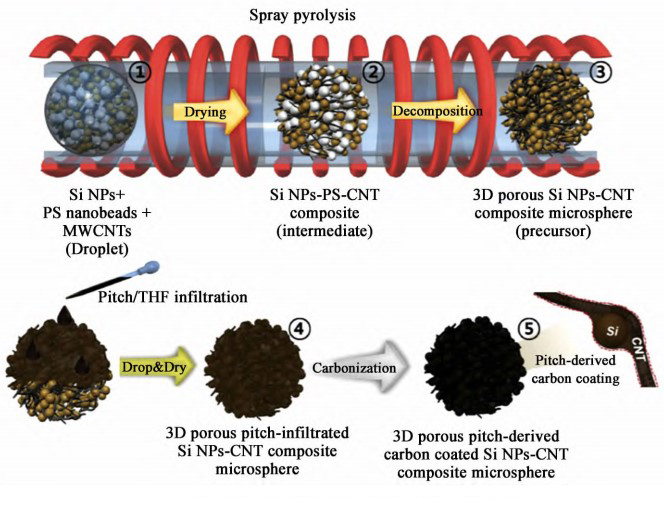

Park G D et al. uniformly dispersed the asphalt in THF and impregnated it into Si-CNT microspheres, and then carbonized it at 900 ℃ for 3 h in Ar atmosphere to obtain three-dimensional porous asphalt carbon-coated Si-Nano particle-carbon nanotube (Si-CNT-PC) composite microspheres. The preparation process is shown in Figure 5. Compared with si-CNT microspheres without asphalt carbon coating, the carbon-coated silicon nanoparticles show good electrochemical properties. When the current density is 1 A·g-1, after 200 cycles, The maximum capacities of SI-CNT and SI-CNT-@PC are 51 mAh·g-1 and 1 209 mAh·g-1, respectively.

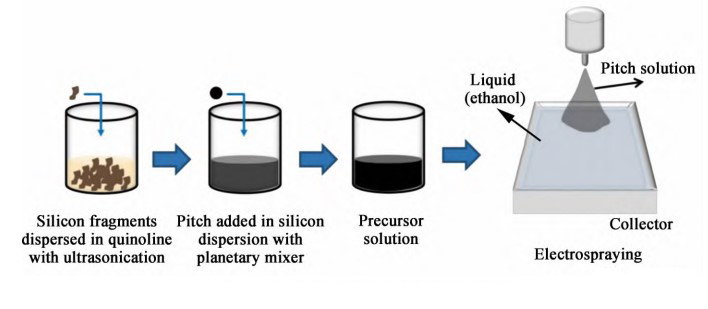

Chen C Y et al. used a planetary ball mill to evenly mix asphalt and silicon debris, and prepared asphalt based silica carbon composite with porous structure as the anode of lithium ion battery by simple electrodeposition and thermal processing. The preparation process is shown in Figure 6. The results show that the composite p-Si-0.5 (asphalt to silicon ratio of 0.5) has a capacity of 1 515 mAh·g-1 and a retention rate of 73.95% after 100 charges at 0.2C. After 200 charges at 0.5C, the capacity is 929 mAh·g-1 and the capacity retention rate is 70.61%.

Liu W et al. used spray drying method to compound silicon nanocrystals with graphite to obtain graphite-loaded silicon nanocrystals (G@Si). Then, asphalt and G@Si composites were rapidly fused at a rotational speed of 2 000 r/min and carbonized at 1 100 ℃ for 2 h. The core-shell G@Si@C composite was successfully prepared. The results show that the initial reversible charging capacity is 502.5 mAh·g-1, coulomb efficiency is 87.5%, and capacity retention rate is 83.4% after 400 cycles.

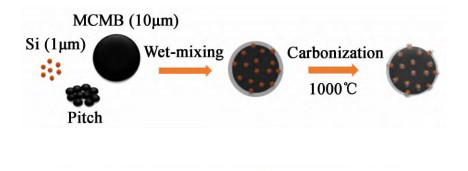

Hsu Y C et al. selected mesophase carbon microspheres as the core carbon precursor, and then added nano-sized silicon on the surface to increase the reversible capacity. After that, asphalt was coated on the surface of silicon carbon composite material at high temperature to obtain a double-core-shell carbon/silicon/graphite composite material. The preparation process is shown in Figure 7. The silicon carbon anode material was coated with bituminous carbon on the surface, which successfully cushioned the capacity damage caused by the volume expansion of silicon. When the optimum silicon content was 30%, the capacity could reach 650 mAh·g-1. After 500 cycles, the capacity retention rate was 79%, and the Coulomb efficiency remained at 99%.

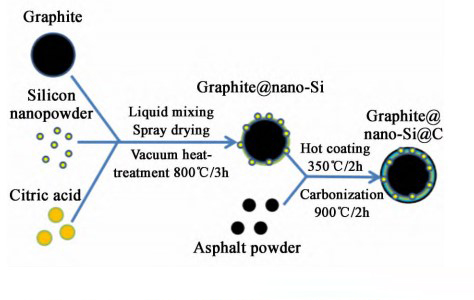

Liu W et al. first mixed silicon nano powder, graphite powder and citric acid evenly, and then synthesized graphit@ nano silicon composite by spray drying and vacuum heat treatment. In order to reduce the specific surface area of the composite material, a certain proportion of asphalt powder and graphite-nano-silicon composite material were put into a thermal reactor, stirred at 350 ℃ for 2 h, and then carbonized at 900 ℃ for 2 h under the protection of nitrogen. The preparation process is shown in Figure 8. The first discharge capacity of graphite-nano-silicon composite is 582.1 mAh·g-1, the first Coulomb efficiency is 90.31%, and the capacity retention rate of graphite-nano-silicon composite is 66.03% after 300 cycles. However, after 300 cycles, The capacity retention rate is 84.51%, and the initial discharge capacity is 618.8 mAh·g-1.

Qu F et al. uniformly dispersed bitumen powder and silicon microspheres (SiMS) with micro/nano hierarchical structure in TETRAhydrofuran. The solvent was then dried at 70 ℃ to evaporate, and the solid mixture was then protected by nitrogen. The asphalt-coated silicon carbon composites were carbonized for 3 h at 900 ℃ at a heating rate of 5 ℃·min-1. The discharge capacities of SiMS, CSiMS and C as anode materials of lithium-ion batteries were compared, and the relationship between the coulombic efficiency and the number of cycles was compared. Compared with SiMS and C, C-SIMS coated with bituminous carbon showed the best electrochemical properties.

Although asphalt is widely used in industry, its composition and structure are complicated due to the diversity of raw materials and processing technology. In the production process, due to the long screening time of raw asphalt, the instability of the screening process leads to the increase of cost and the low consistency of the finished product. Therefore, the development of special asphalt for lithium ion battery anode materials and the rapid detection of asphalt are also the focus of the subsequent asphalt modified anode materials.

It has been pointed out that the TI (β resin) and TS (γ resin) components of bitumen are related to the yield and fluidity of bitumen respectively. Therefore, it is of great significance to study the physical/chemical properties of asphalt as the carbon precursors of negative electrode materials, and to explore the relationship between different components of asphalt and the performance indexes of the final application in the negative electrode of lithium ion batteries. It can not only fully explore the mechanism of action of asphalt in the field of electrochemistry from a scientific point of view, but also simplify the confirmation of asphalt characteristics in the process of screening asphalt from the Angle of practice, and guide production to select the optimal asphalt in the shortest time.

At the same time, as a key step of graphite anode material, the flue gas and dust generated during the carbonization process of asphalt coating also need corresponding environmental treatment measures to avoid environmental pollution as far as possible. Reducing the use of asphalt with low softening point and developing fume treatment technology are also the key problems in the rapid development of lithium ion battery industry.

Copyright © 2022. Prominer (Shanghai) Mining Technology Co.,Ltd.Technical Support : Qianxing | Privacy Policy