- (+86) 021-60870195

- No.2555,Xiupu Road, Pudong, Shanghai

- [email protected]

PROMINER are ready to do our best to assist the client from the worldwide to be professional anode material manufacturer.

With the successive announcement of energy conservation and emission reduction targets in various countries around the world, the development of clean energy and the promotion of green travel have gradually become the mainstream of energy development. In this context, industries such as new energy vehicles, clean energy power generation and energy storage are developing rapidly, which has led to the rapid development of power and energy storage batteries. At present, the focus of development is mainly on lithium-ion batteries. As an important part of lithium-ion batteries, the anode material industry has made rapid progress in the past five years, especially in China. The status of leading companies in the industry has gradually stabilized, and new projects have accelerated. It is also in this wave that Prominer has accumulated rich experience in anode material production lines from the initial simple equipment manufacturing to undertaking the design and construction of anode material production lines.

Prominer is committed to the research and development of equipment manufacturing and anode material production processes related to graphite anode material production lines, and has rich experience in anode material production line construction. At the same time, our technical service team has many senior engineers who have worked in leading anode material companies for many years and have rich industry experience, and can provide a complete set of solutions for anode material production lines, including product positioning, process design, and equipment manufacturing. Supply, production line construction services and operation and maintenance services.

※ Providing the complete system for ultra-fine powder grinding, micron or submicron size powder classification, pneumatic conveying, high-precision measuring and batching control, storage and packing with automation control system.

※ Providing the complete solution for anode & cathode material production line include grinding, shaping, purification, granulation, coating, carbonization, graphitization and final product packing systems.

※ Lab & pilot test service for ultra-fine powder grinding, classification for all kinds materials in our factory. By working together with our partners, we can also provide the test work for anode & cathode material purification, granulation, coating, carbonization, graphitization and the coin cell & full cell test for lithium battery.

※ One stop service for mass production plant for anode material, cathode material and all kinds of material ultra-fine powder processing project include engineering design, equipment procurement, installation & commissioning and operation & maintenance services.

Lithium-ion batteries have many advantages such as high energy density, long cycle life, small self-discharge, no memory effect, and environmental friendliness. They have been widely used in consumer electronics fields such as smartphones, smart bracelets, digital cameras, and notebook computers, with the largest consumer demand. At the same time, it is gradually being promoted in the field of pure electric, hybrid electric and extended-range electric vehicles, and the growth trend of market share is the largest. In addition, lithium-ion batteries also have a good development trend in large-scale energy storage fields such as power grid peak regulation, home power distribution and communication base stations.

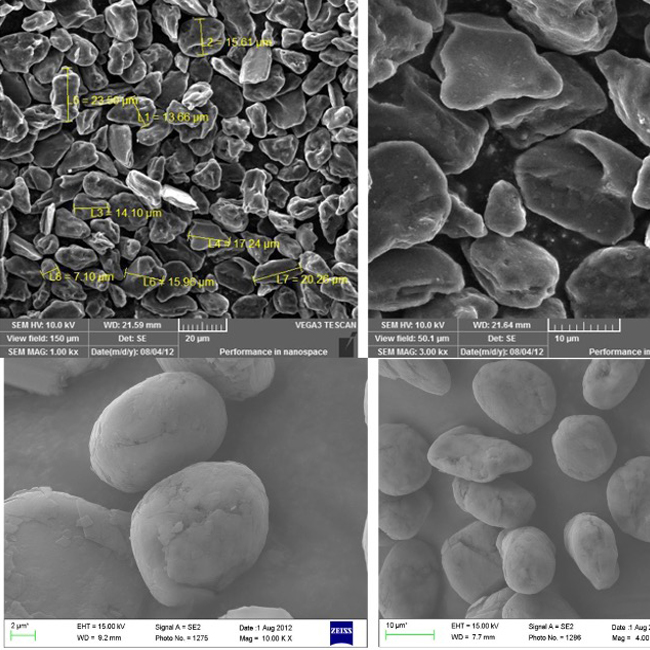

Lithium-ion batteries are mainly composed of positive electrodes, negative electrodes, electrolytes and separators, among which the choice of anode materials will directly affect the energy density of the battery. Anode materials are mainly divided into carbon-based materials and non-carbon-based materials. At present, the mainstream anodes are still natural graphite and artificial graphite in carbon-based materials. Natural graphite is mined from mines and made through flotation, spheroidization and surface coating, while artificial graphite is made from coal tar pitch or vacuum residue, a by-product of petroleum or coal chemical industry, and is made into needle-shaped by delayed coking. and made by granulation and graphitization. Read More

Copyright © 2022. Prominer (Shanghai) Mining Technology Co.,Ltd.Technical Support : Qianxing | Privacy Policy