- (+86) 021-60870195

- No.2555,Xiupu Road, Pudong, Shanghai

- [email protected]

No.2555,Xiupu Road, Pudong, Shanghai

(+86) 021-60870195

We Sincerely Welcome You To Contact Us Through Hotlines and Other Instant Communication Ways.

Lithium-ion batteries have many advantages such as high energy density, long cycle life, small self-discharge, no memory effect, and environmental friendliness. They have been widely used in consumer electronics fields such as smartphones, smart bracelets, digital cameras, and notebook computers, with the largest consumer demand. At the same time, it is gradually being promoted in the field of pure electric, hybrid electric and extended-range electric vehicles, and the growth trend of market share is the largest. In addition, lithium-ion batteries also have a good development trend in large-scale energy storage fields such as power grid peak regulation, home power distribution and communication base stations.

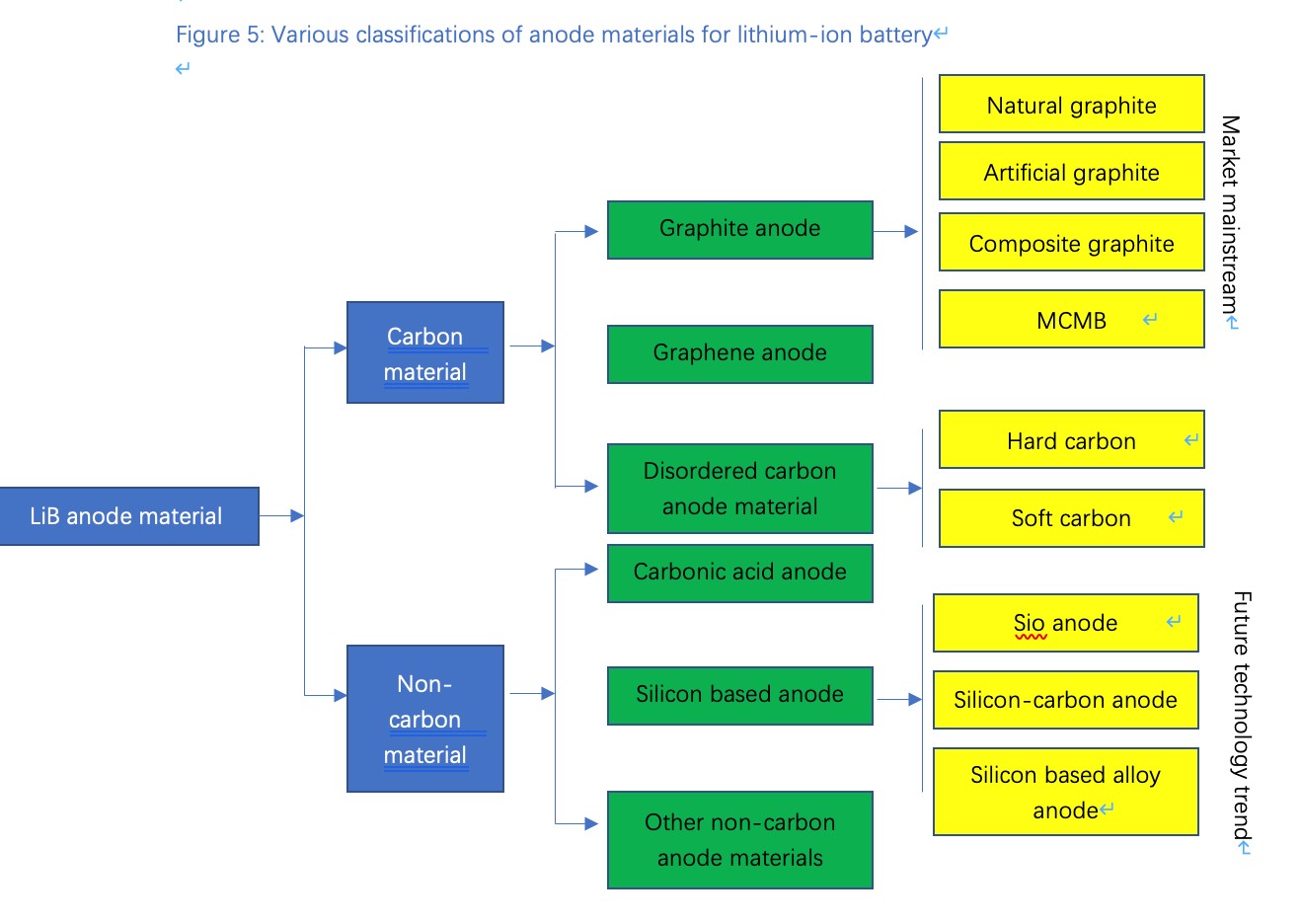

Lithium-ion batteries are mainly composed of positive electrodes, negative electrodes, electrolytes and separators, among which the choice of anode materials will directly affect the energy density of the battery. Anode materials are mainly divided into carbon-based materials and non-carbon-based materials. At present, the mainstream anodes are still natural graphite and artificial graphite in carbon-based materials. Natural graphite is mined from mines and made through flotation, spheroidization and surface coating, while artificial graphite is made from coal tar pitch or vacuum residue, a by-product of petroleum or coal chemical industry, and is made into needle-shaped by delayed coking. and made by granulation and graphitization.t

As the core component of lithium-ion batteries, the anode material usually needs to meet the following conditions during application:

1. The structure is relatively stable during the charging and discharging process and has a long cycle life;

2. High electronic conductivity, ionic conductivity and low charge transfer resistance to ensure small voltage polarization and good rate performance;

3. It can form a stable solid electrolyte membrane with the electrolyte to ensure high Coulombic efficiency;

4. The preparation process is simple, easy to industrialize, and the price is cheap;

5. Environmentally friendly, it will not cause serious pollution to the environment during the production and actual use of materials;

6. Abundant resources, etc.

Anode materials can be roughly divided into two categories according to the types of raw materials and manufacturing processes: carbon materials and non-carbon materials. Among the carbon materials, graphitized carbon materials are the most important anode materials, among which natural graphite, artificial graphite, and mesocarbon microspheres have large-scale industrial applications. Among the non-carbon materials, lithium titanate has also been well applied in the field of energy storage and fast charging batteries; the new anode material silicon carbon composite material is also moving towards industrial application.

Graphite is widely used because of its good consideration of the above conditions. In addition, although Li4Ti5O12 has low capacity and high lithium intercalation potential, its structure is stable during charge and discharge, allowing high rate charge and discharge, so it also has certain applications in power batteries and large-scale energy storage. Generally speaking, the key technical indicators of anode materials are: crystal structure, particle size distribution, tap density, specific surface area, pH, water content, main element content, impurity element content, initial discharge specific capacity and initial charge-discharge efficiency, etc.

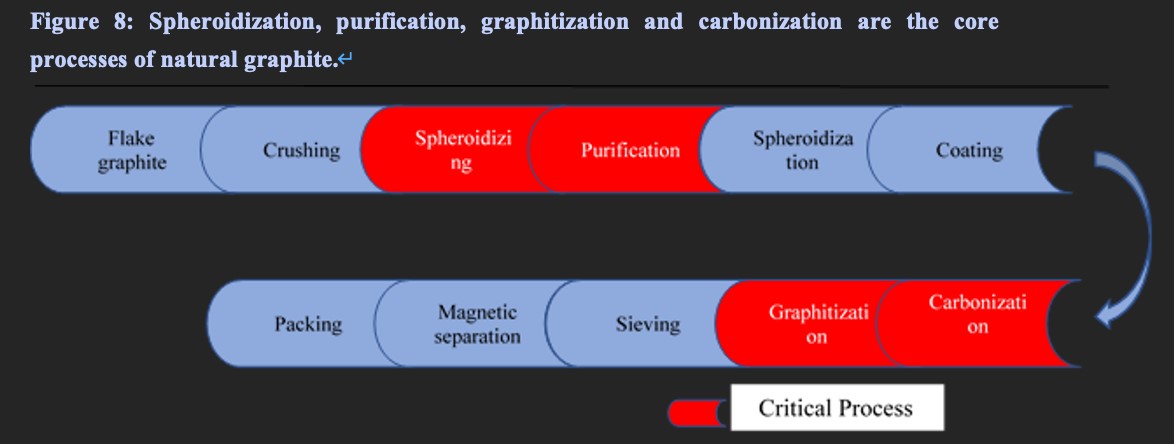

The most upstream of natural graphite is graphite ore, and flake graphite is obtained from graphite ore after flotation. The flotation process includes the steps of raw ore crushing, wet rough grinding, rough separation, coarse concentrate regrinding and reselection, selection, dehydration and drying, and classification and packaging. The flake graphite after flotation is pulverized, spheroidized, and classified to obtain spherical graphite, and the spherical graphite is then subjected to solid phase or liquid phase surface coating and subsequent screening, carbonization and other processes to become the final product: Modified natural graphite anode. Spherical graphite has high impurity content, large crystallite size, and unchangeable structure. It must be modified when used in LIB anode. The purpose is to alleviate the uneven reaction on the carbon electrode surface, so that the SEI film formation reaction on the electrode surface can be uniform. to obtain a good quality SEI film.

Natural graphite products take natural flake spheroidized graphite as the main raw material, which has the following three disadvantages: firstly, natural flake graphite powder has a large specific surface area, which has a huge influence on the first charge and discharge efficiency of the anode; Secondly, the anisotropy of flake graphite and the long diffusion path of lithium ions lead to the low specific capacity; finally, because the graphite has a smaller interlayer spacing, it increases the diffusion resistance of lithium-ion, which makes poor multiplier. When charging quickly, it is prone to safety risks. In order to solve these problems, the manufacturers mainly improve the performance of anode material through spheroidization, modification treatment and high temperature graphitization etc.

Characteristics of NG type anode material:

Low cost;

1. Higher specific capacity;

2. Low charge and discharge voltage plateau;

3. High degree of crystallization;

4. mature technology of purification, crushing and classification

5. Good processability;

6. high compacted density

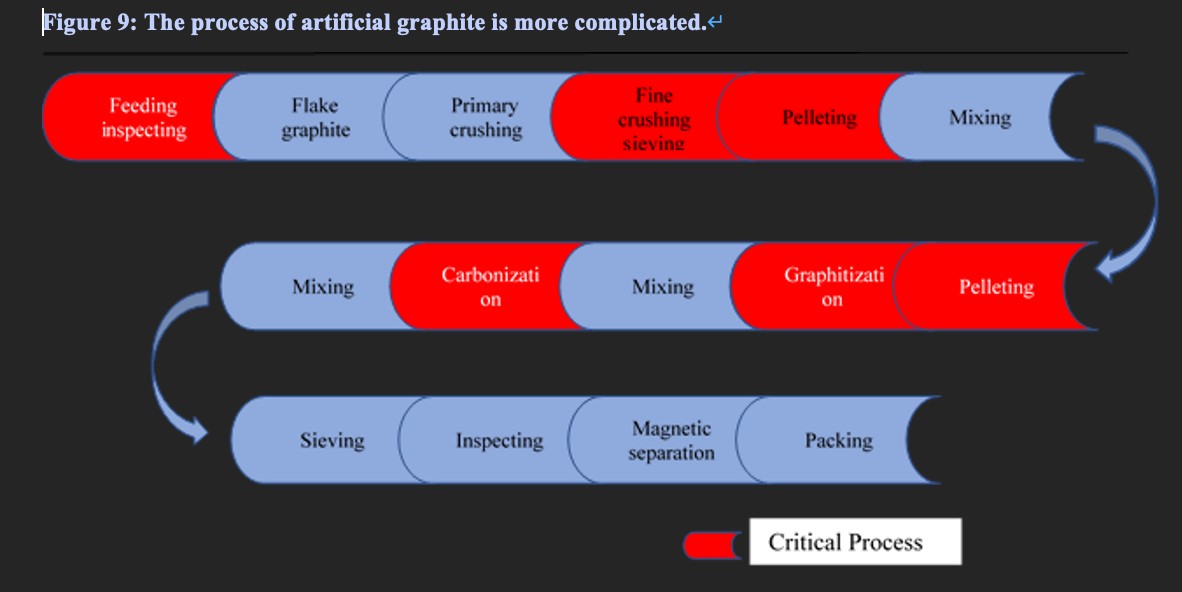

Artificial graphite is a product that converts easily graphitizable carbon (such as pitch coke) into graphite by high-temperature graphitization treatment at 1900-2800 degrees Celsius in nitrogen. Compared with natural graphite, the process flow is longer. Although the cost and sales price of the corresponding artificial graphite of the same grade are higher than those of natural graphite, and the theoretical energy density and electrical conductivity of artificial graphite are also lower than those of natural graphite, its cyclability, safety performance, high-rate charge-discharge efficiency, and electrolysis The compatibility of liquids is better than that of natural graphite; at the same time, the price range and capacity range of artificial graphite have a wide range according to the quality of graphite materials, which are mainly used in power batteries and mid-to-high-end electronic products. Therefore, artificial graphite has the irreplaceable status of natural graphite and is the mainstream direction of anode materials.

Compared with the process of natural graphite, the process of artificial graphite is more complicated, and the product effect is better, which process barrier is higher in special steps. Artificial graphite raw materials are mainly petroleum coke and needle coke, in which the middle and low-end products are mainly petroleum coke, and the high-end products are mainly needle coke. The key steps include raw material inspection, fine crushing classification, secondary granulation and surface modification. The quality of raw materials has a direct impact on the structure of the final artificial graphite products. Taking PUTAILAI as an example, as the leader of artificial graphite in China, the company has its own unique technical advantages in these four processes. In order to meet the demand of fast charging, high-end products will be customized to add a carbonization process. Moreover, because of the difference in process technology, process sequence and manufacturing engineering equipment of each company, the overall product quality is differentiated.

Characteristics of NG type anode material:

1. Good performance on recycle characteristic;

2. Better safety;

3. Suitable for high rate charge and discharge;

4. Good compatibility with electrolyte

Copyright © 2022. Prominer (Shanghai) Mining Technology Co.,Ltd.Technical Support : Qianxing | Privacy Policy