- (+86) 021-60870195

- No.2555,Xiupu Road, Pudong, Shanghai

- [email protected]

No.2555,Xiupu Road, Pudong, Shanghai

(+86) 021-60870195

We Sincerely Welcome You To Contact Us Through Hotlines and Other Instant Communication Ways.

Silicon is currently known as the highest specific capacity of lithium ion anode material, can reach 4200mAh/g, should be the first choice of lithium ion battery anode material, but why has not been widely used? This is due to the limitations of its own crystal structure.

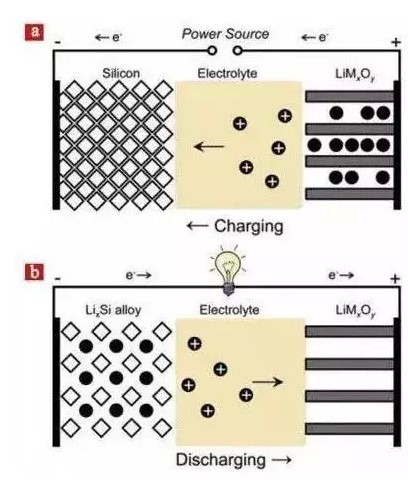

As the anode material, silicon is the charging and discharging principle of the battery as shown below:

Part of the clue can be seen in the figure. During charging, lithium ions are released from the cathode material and embedded into the internal lattice of the silicon crystal, resulting in a large expansion (about 300%), forming a si-Li alloy. The lithium ions fall out of the lattices and form large gaps. Using silicon crystal alone as the anode material is prone to the following problems:

First, in the process of deinlay, there is a significant change in the volume of silicon crystal. Such volume effect is easy to cause the silicon anode material to peel off from the collector, resulting in electrochemical corrosion and short circuit caused by the electrode foil, which affects the safety and service life of the battery.

Second, silicon carbon is an element of the same main group, and SEI will also be coated on the silicon surface when it is charged and discharged for the first time. However, the spalling caused by the volume effect of silicon will lead to the repeated destruction and reconstruction of SEI, thus increasing the consumption of lithium ions and ultimately affecting the capacity of the battery.

So in order to complement each other, what processes can be used to modify and optimize silicon?The composite treatment of silicon and other materials can play a better effect, among which silicon carbon composite material is one of the materials studied more.

Carbon material is the most used anode material at present, carbon material can be divided into soft carbon (graphitized carbon), graphite, hard carbon (amorphous carbon) three, its charge and discharge chemical equation can be expressed as:

Carbon anode materials have good cycling stability and excellent electrical conductivity, and lithium ions have no significant effect on the layer spacing, and can buffer and adapt to the volume expansion of silicon to a certain extent, so they are often used to compound with silicon.

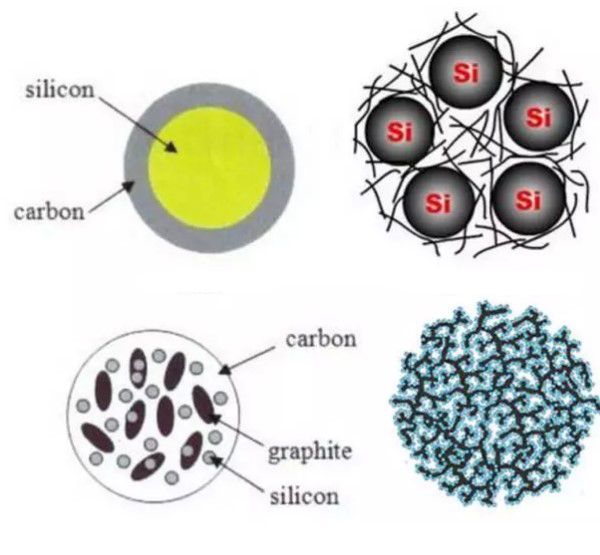

Generally, according to the type of carbon materials, composites can be divided into two categories: silicon carbon traditional composites and silicon carbon new composites. The traditional composite refers to the composite of silicon and graphite, MCMB, carbon black, etc., while the new silicon carbon composite refers to the composite of silicon and carbon nanotubes, graphene and other new carbon nanomaterials.

Silicon carbon anode materials are mainly divided into coating type, embedded type and molecular contact type according to the distribution of silicon, and according to the shape is divided into particles and thin film type, according to the number of silicon carbon type is divided into silicon carbon binary composite and silicon carbon multiple composite. The following figure shows silicon carbon anode materials with different distribution modes:

Silicon carbon composites are prepared by ball milling, high temperature cracking, chemical vapor precipitation, sputtering deposition, evaporation and so on. The reversible capacity of silicon carbon anode prepared by ball milling can reach 500~1000mAh/g. Ball milling can promote the uniform mixing of raw material particles and obtain smaller particle size. At the same time, the gap between particles is also conducive to improve the cycle performance of the battery.

High temperature pyrolysis is a method to obtain Si/C composites by cracking silicon nanoparticles and organic precursors or direct pyrolysis of silicone precursors. The gram capacity of Si/C composites prepared by this method is lower than that of Si/C composites prepared by high-energy ball milling, but higher than that of graphite, about 300~700mAh/g. This is because the electrode material prepared by pyrolysis method contains a large number of substances with no electrochemical activity, which reduces the capacity of the electrode material.

On the other hand, the silicon in the electrode materials prepared by pyrolysis tends to agglomerate and become more likely to fail in subsequent use.

Silicon nanoparticle is an early anode material, but its application is limited by its large expansion volume effect. The composites prepared by the combination of silicon and carbon reserve the expansion space for the volume expansion of silicon, and to some extent make up for the shortcomings of the poor conductivity of silicon and the instability of SEI film, which has been widely concerned and applied by cell manufacturers.

Copyright © 2022. Prominer (Shanghai) Mining Technology Co.,Ltd.Technical Support : Qianxing | Privacy Policy