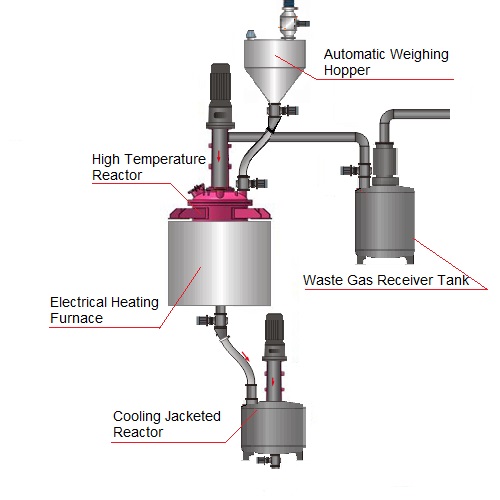

Coating & Granulation System

Coating and granulation processing is the key step in the whole anode material processing and its performance determines the quality of final product. In our design one system combine the coating and granulation processing functions together. It can make the coating material and graphite mixing evenly and sufficiently and the electrical heating device will provide staged heating to help the mixed materials coated.

The development of lithium-ion batteries depends to a large extent on the development and application of high-performance cathode and anode materials. Taking the anode material as an example, the use of a battery anode formed by granulation can not only greatly improve the battery life, but also effectively increase the electric capacity.

The common anode granulation process is to first mix coke and pitch by high-temperature melting, and then proceed through carbonization, graphitization, and other procedures in sequence. First, the coke and pitch are mixed, and then melted using high temperature, so that the coke and pitch can be mixed evenly. The above-mentioned high temperature melting step usually needs to be completed in an environment of about 600-700°C.

After high temperature melting, the coke and pitch mixture is crushed first, and then sieved and classified. The mixture particles with appropriate particle size are screened out, and then carbonization and graphitization are carried out in sequence to obtain materials that can be used for battery anodes.

The complete system contains weighing feeding device, high temperature reactor with electrical heating furnace, cooling jacketed reactor and waste gas receiver tank.

Graphite Coating & Granulation System Technical Features:

※ High precision metering feeding device with tolerance 0.3%

※ PLC automatic control system

※ High-property heat preservation material to reduce the energy consumption.