- (+86) 021-60870195

- No.2555,Xiupu Road, Pudong, Shanghai

- [email protected]

No.2555,Xiupu Road, Pudong, Shanghai

(+86) 021-60870195

We Sincerely Welcome You To Contact Us Through Hotlines and Other Instant Communication Ways.

The anode of lithium ion battery is made of carbon material or non-carbon material, binder and additive, which is mixed into a paste adhesive and evenly coated on both sides of copper foil. After drying and rolling, the anode materials that have been used in lithium ion battery are basically carbon materials. Such as artificial graphite, natural graphite, mesophase carbon microspheres, petroleum coke, carbon fiber, pyrolytic resin carbon, etc.

The anode electrode material needs to be pulverized and processed when it is used, but the existing pulverizing device has the following shortcomings when pulverizing the anode electrode material:

1.Due to the different types of lithium battery anode materials, it is difficult to use the traditional crushing device, and it is not convenient to carry out crushing operations for raw materials with different hardness

2.It is inconvenient to sieve large particles and powders. Due to the incomplete pulverization, the large particles of raw materials are mixed, so that the uniformity of the pulverized raw materials is low, which affects the subsequent use.

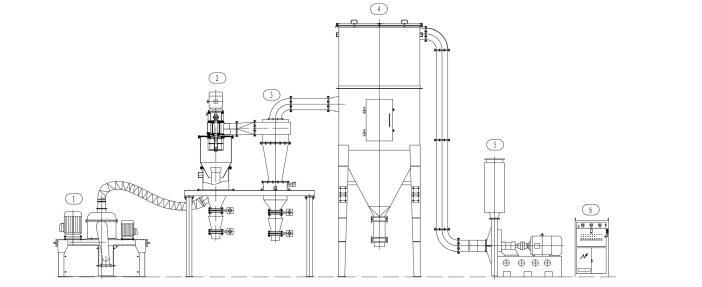

The crushing system of lithium battery anode material includes a bottom box, a crushing mechanism, an extrusion component, and a vibration mechanism. The middle of the bottom box is provided with a crushing shaft that penetrates horizontally and is rotatably connected. The crushing mechanism is installed on the crushing shaft. There are extrusion shafts running through and rotatably connected, and extrusion components are installed on the two extrusion shafts. A semi-circular sieve cylinder is arranged in the bottom box below the pulverizing shaft, and the semi-circular sieve cylinder is connected with the bottom box through a vibrating mechanism.

The utility model solves the problem of incomplete and uneven pulverization of the negative electrode material of the lithium battery through the cooperative use of various mechanism components, and the overall structure is compact, which facilitates the extrusion and crushing of raw materials of different hardness, and avoids large smashing through screening and secondary pulverization. The doping of granular raw materials improves the uniformity of the pulverized raw materials.

Copyright © 2022. Prominer (Shanghai) Mining Technology Co.,Ltd.Technical Support : Qianxing | Privacy Policy