- (+86) 021-60870195

- No.2555,Xiupu Road, Pudong, Shanghai

- [email protected]

No.2555,Xiupu Road, Pudong, Shanghai

(+86) 021-60870195

We Sincerely Welcome You To Contact Us Through Hotlines and Other Instant Communication Ways.

一、Carbon Materials

Carbon material is the most widely used and most common anode material in commercial application today, mainly including natural graphite, artificial graphite, hard carbon, soft carbon, MCNB (mesic carbon microspheres). Before the next generation of anode materials mature, carbon material, especially graphite material will still be the first choice and mainstream of anode materials.

1.1 Graphite

Graphite is divided into natural graphite and artificial graphite according to the difference of its raw materials and processing technology. Because of its advantages of low potential for lithium, high first efficiency, good cycle stability and low cost, graphite has become the ideal anode material in the application of lithium ion batteries.

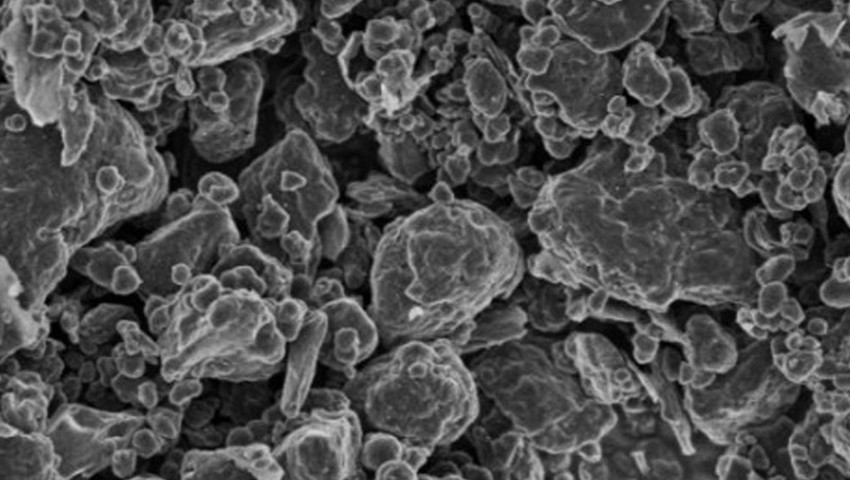

Natural graphite: generally using natural flake graphite as raw material, modified to make spherical natural graphite use. Although natural graphite is widely used, there are several shortcomings: (1) natural graphite surface defects, large specific surface area, the first efficiency is low; (2) Using PC-based electrolyte, there is serious solvated lithium ion co-embedding phenomenon, resulting in graphite layer expansion and stripping, battery performance failure; (3) Natural graphite has strong anisotropy, lithium ion can only be embedded from the end face, poor magnification performance.

Modification of Natural Graphite

①Another approach is to coated modification, natural graphite to amorphous carbon coated, build "core - shell structure" particles, often the amorphous carbon carbon source is low temperature pyrolytic carbon materials such as bitumen, phenolic resin, the existence of the carbon layer can not only out of direct contact with the electrolyte, reduce particle surface active point, reduce the specific surface area, also because of its high carbon layer layer spacing, It can also reduce the interfacial impedance and improve the diffusion ability of lithium ions.

②Aiming at the problem of natural graphite strong anisotropy, industrial production of the spherical particle morphology by mechanical processing means plastic, plastic machine adopts wind airflow impact friction between particles, cutting edges and particles, this method will not introduce doping impurities, spheroidizing of high efficiency, but can lead to a large number of particles pulverization, yield is low. The mechanical fusion machine uses the material in the rotor rotating at high speed, under the action of centrifugal force close to the wall, in the rotor and stator extrusion head through high speed. At this moment, the material is subjected to the action of extrusion pressure and shear force at the same time, under the action of friction between particles and particles and between particles and equipment, the surface presents a mechanical melting state, to achieve the purpose of spherification. After spherification of natural graphite, the particle size D50 range of 15 ~ 20μm, the first efficiency and cycle performance are improved significantly, and the rate performance is greatly improved.

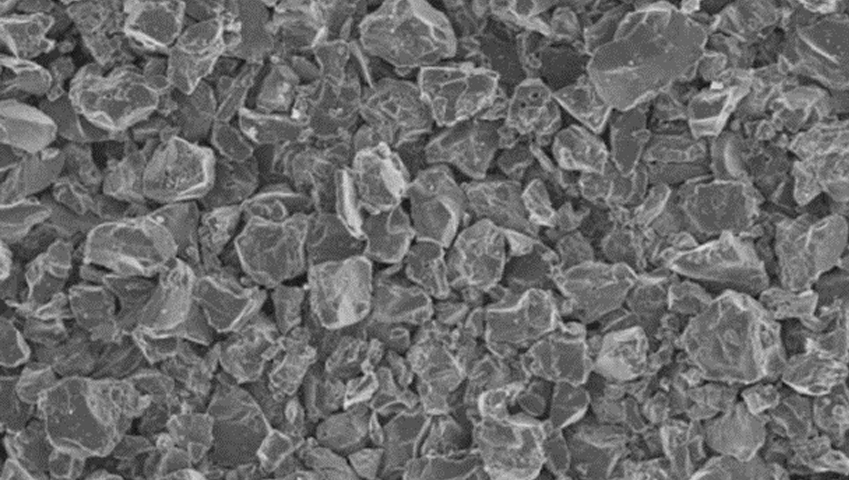

artificial graphite:The modification method of artificial graphite is different from that of natural graphite, which can reduce the orientation of graphite grain (OI value) by recombination of grain structure. Usually, the needle coke precursor with the diameter of 8 ~ 10μm is selected, and the graphitized material such as asphalt is used as the carbon source of the binder. After treatment by the drum furnace, several needle coke particles are bonded, and the secondary particles with the diameter of D50 ranging from 14 ~ 18μm are made. After graphitization, the OI value of the material is effectively reduced.

1.2 Soft Carbon

Generally speaking, according to the difference of precursor sintering temperature, soft carbon will produce three different crystal structures, which are amorphous structure, turbulent layer disorder structure and graphite structure, graphite structure is the common artificial graphite. Amorphous structure is widely concerned because of its low crystallinity, large layer spacing and good compatibility with electrolyte, so it has excellent low temperature performance and good rate performance.

1.3 Hard Carbon

The common hard carbon includes resin carbon, organic polymer pyrolytic carbon, carbon black and biomass carbon, among which phenolic resin is pyrolyzed at 800℃ to obtain hard carbon materials with a capacity of 800mAh/g for the first charge and a layer spacing of D002 > 0.37nm (graphite is 0.3354nm). The large layer spacing is conducive to the embedding and deembedding of lithium ions. Therefore, hard carbon has excellent charge-discharge properties and is becoming a new research focus of anode materials.

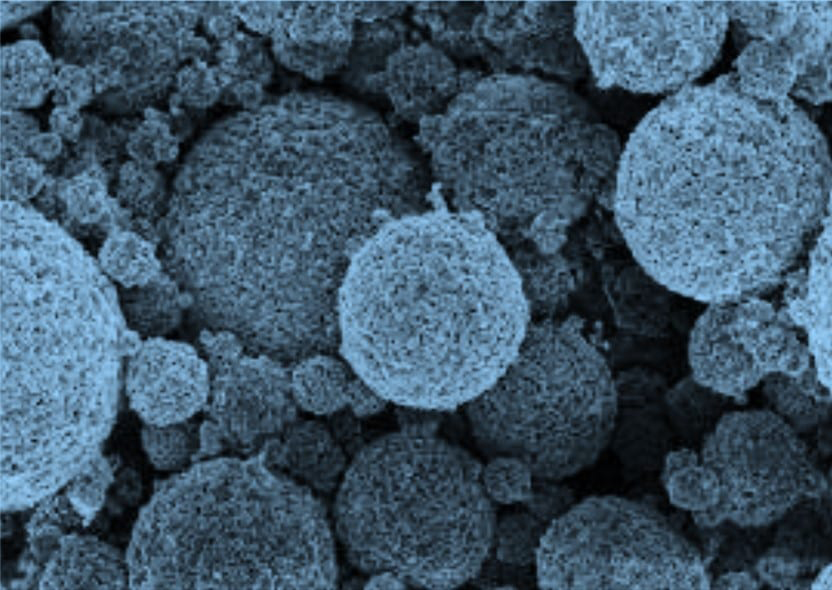

二、Lithium Titanate Material

2.1 Advantage

The theoretical capacity of lithium titanate is 175mAh/g, and the actual capacity is greater than 160mAh/g. It is one of the anode materials that has been industrialized at present.

(1) Zero strain: the cell parameter of lithium titanate a=0.836nm, the insertion of lithium ions during charge and discharge has almost no effect on the crystal structure, avoiding the structural changes caused by material stretching in the process of charge and discharge, so as to have high electrochemical stability and cycle life;

(2) No risk of lithium evolution: lithium titanate has a potential of up to 1.55V for lithium, no SEI film is formed when first charged, high first efficiency, good thermal stability, low interface impedance, excellent low temperature charging performance, charging at -40℃;

(3) THREE-DIMENSIONAL fast ionic conductor: lithium titanate is a three-dimensional spinel structure, lithium embedded space is much larger than the graphite layer spacing, ionic conductivity is an order of magnitude higher than graphite material, especially suitable for large rate charge and discharge.

Disadvantages:

Lithium titanate also has low battery specific energy due to low gram capacity and low voltage platform; Nano-sized materials, high hygroscopicity, resulting in serious high temperature gas production, poor high temperature circulation; The material manufacturing process is complicated and the cost is very high. The cost of the cell is more than 3 times that of the lithium iron phosphate battery with the same energy.

2.2 Material Application and Notes

At present, lithium titanate battery is mainly used in urban pure electric BRT bus, electric hybrid bus, electric frequency modulation peak adjustment auxiliary service and other fields.

Notes: In view of the serious problem of high temperature gas production of lithium titanate, the current industrial production needs to strictly control environmental humidity and water introduction during operation; New additives were added to the electrolyte to inhibit side reaction between lithium titanate and electrolyte. Improve the purity of raw materials, avoid the introduction of impurities in the manufacturing process.

Copyright © 2022. Prominer (Shanghai) Mining Technology Co.,Ltd.Technical Support : Qianxing | Privacy Policy