- (+86) 021-60870195

- No.2555,Xiupu Road, Pudong, Shanghai

- [email protected]

No.2555,Xiupu Road, Pudong, Shanghai

(+86) 021-60870195

We Sincerely Welcome You To Contact Us Through Hotlines and Other Instant Communication Ways.

Natural graphite according to its crystal level is not the same, can be divided into crystalline graphite (scale) and cryptocrystalline graphite (soil) two categories. The characteristics of crystalline graphite minerals are not high grade, stable carbon composition is generally not more than 10%, some special gathering areas reach 20% or more, but this kind of graphite minerals are easy to grind, flotation titanium concentrate level reaches 85% above, is one of the minerals with very good floatability in nature. The price of conductive graphite materials, the level of cryptocrystalline graphite is higher, the stable carbon composition is generally 60 ~ 80 percent, up to 95 percent, but the mineral abrasive is not good.

Graphite powder products in industrial production on the use of gradually widespread, graphite powder products research and development from low-end, middle to high block, the price of conductive graphite material, high purification of graphite powder products and particle size is the key two basis, high purity graphite powder is a representative product of high purification of graphite powder

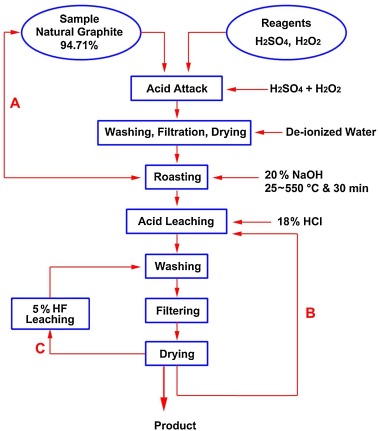

High purity in high-purity graphite powder refers to the high purity of graphite powder, which specifically refers to the proportion of carbon content in graphite powder. The purity of high-purity graphite powder is generally above 99.9%. It is known at this stage. The high-purity graphite powder extraction technologies include high-temperature graphitization method, sodium peroxide melting method, high-concentration strong acid method, and triple-strong acid extraction method. Ninety-eight to ninety-nineth of the flake graphite powder is used as the material, using strong sulfuric acid, hydrochloric acid and hydrogen fluoride to scientifically and rationally mix it with the flake graphite powder. Add these three types of acid in the corresponding order, and stir and mix well. The price of conductive graphite material makes the chemical reaction between the graphite powder and the three acid solutions within 24 hours, and then discharges the waste acid, cleans the graphite powder with industrial production cleaning water until it becomes neutral, and then cleans it with pure water for two to After five times of dehydration, the graphite powder is dehydrated with a centrifugal dehydrator, and the graphite powder is dried and processed, and then sampled and packaged into high-purity graphite powder, so that the finished product is completed.

Copyright © 2022. Prominer (Shanghai) Mining Technology Co.,Ltd.Technical Support : Qianxing | Privacy Policy